The Essential Role of WiFi in Warehouse Operations

In recent years, the logistics sector has undergone significant modernisation. These new methods, closely dependent on connectivity, have made the presence of WiFi in warehouses almost indispensable. However, the implementation of such a professional network faces various pitfalls.

The connected warehouse, an approach that is now imperative

In the past, warehouses were managed in a rudimentary way. Stock tracking was done on a local computer or even on paper, which inevitably led to errors and a lack of reactivity.

Since the rise of the Internet and e-commerce sites, such management has become obsolete. The function of the business space has evolved to become a real "hub" between multiple players: employees, suppliers, transport providers, distributors, customers, etc. New challenges have emerged, particularly with regard to the traceability of information and its availability in real time.

The logistics sector has therefore integrated a wide variety of new technologies: barcode scanners, QR codes, RFID, ERP (Enterprise Resource Planning) or WMS (Warehouse Management System) software, etc. All of these elements are designed to retrieve, store, transmit, maintain and archive data on goods. And the digital transformation of logistics is set to intensify in the coming years, with the increasing use of automation and IoT (Internet of Things).

Wireless network as the backbone of the digitalisation of logistics

The above-mentioned technologies have one thing in common: to be effective, they must be able to communicate with each other. For example, an e-commerce platform can only provide information about the availability of products if it is closely linked to the inventory management system.

In this sense, a professional WiFi network is the backbone of the digitalisation of logistics. It provides instantaneous data transmission between the various components of the information system. In this way, the company can meet the new requirements of its customers and partners. But the connected warehouse also helps employees by simplifying their tasks and reducing the risk of error. The result is higher productivity and lower costs.

Handhelds (to scan products) and tablets (to access information systems), essential equipment in warehouses, are connected through the wireless network!

Handhelds (to scan products) and tablets (to access information systems), essential equipment in warehouses, are connected through the wireless network!

The most recent WiFi access points even make it possible to envisage converged infrastructures - combining WiFi and IoT - thanks to integrated IoT functionalities and/or dedicated hardware ports. This makes it possible to rationalise the costs of deploying several services around the same infrastructure and to take advantage of the latest technological advances in digitisation and automation.

However, these benefits can only be achieved if the network infrastructure is reliable, correctly sized and adapted to the environment. In the connected logistics environment, there are a large number of obstacles to overcome in order to achieve optimal radio coverage, whether it is WiFi or IoT related.

Difficulties in deploying WiFi in warehouses

Indeed, warehouses are not like other business premises, firstly because of their size: large surface area to cover, high ceilings, etc. Logically, WiFi cannot be installed in a warehouse in the same way as it would in a traditional office, at the risk of creating "white zones", which would seriously hamper the teams on a daily basis.

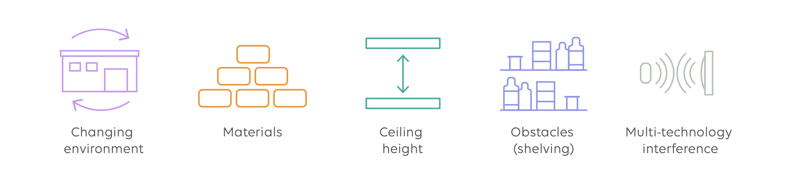

In addition, stored items, such as shelving, may be made of metallic materials, which hinder the propagation of waves. These conditions also vary depending on the shipment and transport of goods. The professional wireless network must therefore adapt to a hostile and inconsistent environment.

Finally, the number of connected devices in the building and their diversity must be taken into account. WiFi must be able to support the weight and adapt to changes, particularly those linked to the arrival of IoT.

In a warehouse, there are 3 of the 4 main obstacles to deploying a Wi-Fi infrastructure

Productivity is definitely dependent on WiFi connectivity in a warehouse. Therefore, all of these features must be taken into account when thinking about the implementation of the wireless network.

WiFi: a productivity driver rather than a cost source for logistics warehouses

As you can see, although a high-performance, reliable WiFi solution may at first sight represent a major source of investment for a warehouse, it will quickly turn into a source of savings compared to a failing network. Given the criticality of the wireless network, using a professional WiFi operator is a wise choice to equip your logistics facilities. It will guarantee a tailor-made deployment thanks to a precise methodology of radio audit and on-site installation. It will then ensure that the infrastructure is maintained in operational conditions on a daily basis, for a network that works perfectly, everywhere, all the time!

- Wifi (35)

- Hotel Industry (18)

- Digital Workplace (13)

- Behind the scenes (8)

- IPTV - Signage (8)

- Optical fibre (7)

- Green-IT (5)

- Retail (5)

- Education (3)

- Healthcare (2)

- Cybersecurity (1)

- General (1)

- Hospitality (1)

- PBSA (1)

- Student Accommodation (1)

- Telephony (1)

- Tips and tricks (1)

- Tourism (1)

- Wifirst (1)

You May Also Like

These Related Stories

The Importance of High-Performance WiFi

The Wagner Project - An orchestrator at the heart of Wifirst’s strategy